Introduction

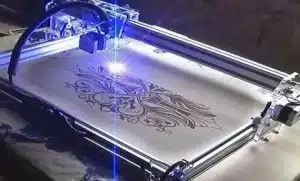

Laser engraving is now a favorite technique for making accurate, indistinctive marks on many materials, particularly metals. Its high accuracy in producing complex designs makes it perfect for industrial, commercial, and artistic use. Still, not all metals are equally suitable for laser engraving. Certain metals yield clean, sharp results, whereas others are problematic because of their structure and reflectivity. Knowing which metals can be used for laser engraving and which cannot save time and guarantee a high-quality finish.

Optimal Metals for Laser Engraving

1. Stainless Steel

Stainless steel is a widely used metal in laser engraving because it is powerful and corrosion-resistant. It reacts well to fiber and CO2 lasers, making high-contrast, fine engravings. Stainless steel can withstand heat distortion and can be used in intricate designs and deep markings.

2. Aluminum

Aluminum is light, resistant to corrosion, and very sensitive to laser engraving. Anodized aluminum produces excellent results explicitly since the anodized layer provides contrast and color differences. The surface can absorb the laser beam properly, producing well-defined, sharp engravings.

3. Brass

Brass is a softer metal, so it is simple to engrave using a laser. It leaves bright, shiny engravings with a very high degree of detail. Due to its reflective properties, a fiber laser or a coating could be applied to the material to enhance laser absorption and minimize scattering.

4. Copper

Copper’s high reflectivity and thermal conductivity can render laser engraving difficult. However, using the proper settings and a fiber laser, copper can create attractive, clean engravings. Surface treatments or oxidation can provide for black or dark engravings.

5. Titanium

Titanium is extremely tough and corrosion-resistant, which makes it perfect for high-precision uses. Laser engraving titanium produces permanent, high-contrast marks that do not fade or wear away. It’s frequently utilized in aerospace, medical, and jewelry manufacturing.

Metals That Don’t Work Well for Laser Engraving

1. Gold and Silver

Although gold and silver are malleable and pliable to process with standard engraving tools, they are very hard to work on with a laser due to their high reflectivity. The laser beam does not penetrate much but reflects off the surface, leaving one with an undesirable engraving outcome.

2. Zinc

Zinc’s reactivity to heat and low melting point render it inappropriate for laser engraving. When subjected to a powerful laser, the metal tends to warp or create rough, uneven engravings.

3. Lead

Lead is toxic and has a low melting point, which renders it inappropriate for laser engraving. Laser heat can release harmful fumes, which are dangerous to health.

Conclusion

Laser engraving on metals involves understanding the characteristics of each metal to produce the optimal results. Stainless steel, aluminum, brass, copper, and titanium are some of the most suitable metals for laser engraving because they are complex and reactive to laser energy. Reflective and low-melting-point metals such as gold, silver, zinc, and lead are difficult. By choosing the proper metal and the appropriate laser settings, you can produce high-quality, durable engravings for many uses.

No comment yet, add your voice below!